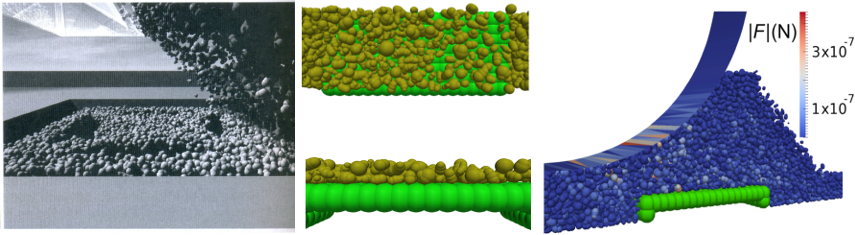

Additive manufacturing constitutes a promising production technology with potential application in a broad range of industrial areas. In this type of manufacturing process, objects are created from powder particles by adding layers of material upon one another through selectively melting particles from the powder bed. However, understanding the mechanical behavior of the powder during manufacturing as a function of material properties and particle shape is an essential pre-requisite for optimizing the production process. We develop a numerical tool for modelling the transport mechanism of powder particles during additive manufacturing based on the Discrete Element Method (DEM). Our numerical tool accounts for the complex geometric shape of the powder particles as well as for the dynamic boundary conditions inherent to the manufacturing process.

Granular Flows

Publications

Weight of an Hourglass – Theory and Experiment in Quantitative Comparison

American Journal of Physics 85, 98

(2017)

Helical inner-wall texture prevents jamming in granular pipe flows

Soft Matter 11, 4295-4305

(2015)

- Jonathan Kollmer

- Martin Tupy

- Michael Heckel

- Achim Sack

- Thorsten Pöschel

Absence of Subharmonic Response in Vibrated Granular Systems under Microgravity Conditions

Physical Review Applied 3, 024007

(2015)

Self-organized Shocks in the Sedimentation of a Granular Gas

Physical Review E 91, 062214

(2015)

- Eric Josef Ribeiro Parteli

- Jochen Schmidt

- Christina Blümel

- Karl-Ernst Wirth

- Wolfgang Peukert

- Thorsten Pöschel

Numerical study of the packing density of fine powders by means of the Discrete Element Method

85th Annual Meeting of the International Association of Applied Mathematics and Mechanics – GAMM 2014, March 10-14

(2014)

- Thomas Päthz

- Eric Josef Ribeiro Parteli

- Jasper F. Kok

- Hans J. Herrmann

Analytical model for flux saturation in sediment transport

Physical Review E 89, 052213

(2014)

- Chuan-Yu Wu

- Thorsten Pöschel

Micro-mechanics and dynamics of cohesive particle systems

Granular Matter 15, 389-390

(2013)

Using LIGGGHTS for performing DEM simulations of particles of complex shapes with the multisphere method

Proceedings of the 6th International Conference on Discrete Element Methods, pp. 217 - 222

(2013)

DEM simulation of particles of complex shapes using the multisphere method: Application for additive manufacturing

AIP Conference Proceedings 1542, 185-188

(2013)

- Thomas Pähtz

- Jasper F. Kok

- Eric Josef Ribeiro Parteli

- Hans J. Herrmann

Flux saturation length of sediment transport

Physical Review Letters 111, 218002

(2013)

- Thorsten Pöschel

- Dietrich E. Wolf

Isaac Goldhirsch: a pioneer of granular matter theory

Granular Matter 14, 77

(2012)

Recurrent Inflation and Collapse in Horizontally Shaken Granular Materials

Physical Review E 85, 031307

(2012)

- Andreas Bauereiß

- Eric Josef Ribeiro Parteli

- Daniel Riedelbauer

- Michael Stingl

Numerische Simulation pulver- und strahlbasierter additiver Fertigungsprozesse

Industriekolloqium des Sonderforschungsbereichs 814 – Additive Fertigung (Drummer, D.; Ed.), 117 – 130

(2012)

- Javier Brey

- Isaac Goldhirsch

- Thorsten Pöschel

Granular Gases: Beyond the Dilute Limit

EPJ Special Topics 179

(2009)

- Marcus Bannerman

- Thomas E. Green

- Paul Grassia

- Leo Lue

Collision statistics in sheared inelastic hard spheres

Physical Review E 79, 041308

(2009)

Hourglass of constant weight

Granular Matter 10, 231-232

(2008)

- Thorsten Pöschel

- Nikolai Brilliantov

- Arno Formella

- Michael Heckel

- Christof Krülle

- Patric Müller

- Clara Salueña

- Thomas Schwager

Contact of granular particles and the simulation of rapid flows using event-driven molecular dynamics

European Journal of Environmental and Civil Engineering 12, 827-870

(2008)

Traffic and Granular Flow'05

(Andreas Schadschneider, Thorsten Pöschel, Reinhard Kühne, Michael Schreckenberg, Dietrich E. Wolf), Springer

(2007)

Scaling properties of granular materials

Physical Review E 64, 011308

(2001)

Can we scale granular systems?

Powders and Grains 2001: Proceedings of the Fourth International Conference on Micromechanics of Granular Media, Sendai, 21-25 May 2001 (Kishino, Y.), 439-442. Rotterdam: Balkema.

(2001)

- Simon Renard

- Thomas Schwager

- Thorsten Pöschel

- Clara Salueña

Vertically shaken column of spheres. Onset of fluidization

European Physical Journal E 4, 233-239

(2001)

Dynamics of granular systems (in German)

Logos, Berlin

(2001)

Molecular dynamics of comminution in ball mills

European Physical Journal B 16, 169–182

(2000)

Convection in horizontally shaken granular material

European Physical Journal E 1, 55-59

(2000)

- Thorsten Pöschel

- Stefan Luding

Granular Gases

Lecture Notes in Physics, 564, Springer, Berlin, Heidelberg, New York

(2000)

Onset of fluidization in vertically shaken granular material

Physical Review E 62, 1361-1367

(2000)

- Clara Salueña

- Thorsten Pöschel

- Sergei E. Esipov

Dissipative properties of vibrated granular materials

Physical Review E 59, 4422-4425

(1999)

Dynamics of granular systems - Theory, experiments, and numerical experiments (in German)

habilitation thesis, Humboldt-University Berlin

(1999)

Rolling friction of a viscous sphere on a hard plane

Europhysics Letters 42, 511-516

(1998)

Interaction of a granular stream with an obstacle

Granular Matter 1, 33-41

(1998)

Is there a critical acceleration for the onset of convection?

Physics of Dry Granular Media: Proceedings of the NATO Advanced Study Institute, Cargese, France, September 15-26, 1997 (H. J. Herrmann and J.-P. Hovi and S. Luding) 350, 625-631. Dortrecht: Kluwer.

(1998)

- Clara Salueña

- Sergei E. Esipov

- Thorsten Pöschel

- Stephan S. Simonian

Dissipative properties of granular ensembles

Proceedings 3327, Smart Structures and Materials 1998: Passive Damping and Isolation, 19-26

(1998)

- Tino Riethmüller

- Lutz Schimansky-Geier

- Dirk Rosenkranz

- Thorsten Pöschel

Langevin equation approach to granular flow in a narrow pipe

Journal of Statistical Physics 86, 421-430

(1997)

- Jason Gallas

- Hans Herrmann

- Thorsten Pöschel

- Stefan Sokołowski

Molecular dynamics simulation of size segregation in three dimensions

Journal of Statistical Physics 82, 443-450

(1996)

- Michael Scherer

- Volkhard Buchholtz

- Thorsten Pöschel

- Ingo Rehberg

Swirling granular matter: from rotation to reptation

Physical Review E 54, R4560(R)

(1996)

Avalanche statistics of sand heaps

Journal of Statistical Physics 84, 1373-1378

(1996)

Complex flow of granular material in a rotating cylinder

Chaos, Solitons & Fractals 5, 1901-1905, 1907-1912

(1995)

- Thorsten Pöschel

- Hans J. Herrmann

Size segregation and convection

Europhysics Letters 29, 123-129

(1995)

- Volkhard Buchholtz

- Thorsten Pöschel

- Hans-Jürgen Tillemans

Simulation of rotating drum experiments using non-circular particles

Physica A 216, 199-212

(1995)

Recurrent clogging and density waves of granular material flowing through a narrow pipe

Journal de Physique I France 4, 499-506

(1994)

Granular material flowing down an inclined chute: A molecular dynamics simulation

Journal de Physique II France 3, 27-40

(1993)

- Thorsten Pöschel

- Harald Puhl

Computer simulations of clogged pipes

KFA-Intern, 24, 3-4

(1993)